FAQs

About XS

Homeless doors and windows seeking adoption! The orphanage is Woodworkers bargain barrel of joinery (doors plus windows and more) and hardware that is discounted between 5% and 80% depending on its popularity & condition. Most items are between 20% and 30% off our trade price and the majority are in a fully waranteed first grade condition. If you have flexibility in your joinery sizes and its design, you can make very significant savings and the product you get will be fully serviceable.

There are 3 levels of warranty within the orphanage. The warranty does not cover any work or alteration made to the item after it is dispatched. Colour differences in the same timber species are not classified as a defect (it is accepted that the sill will most often be of a different timber species than the rest of the frame). Warranty does not cover any timber item purchased that does not have the recommended finish system applied within 24 hours of receipt of the item.

Grade 1 Material & labour warranty (Six months from time of purchase)

Covers any manufacturing fault and defects as defined by AS2688 If the item is deemed by Woodworkers to have a manufacturing fault, it will be altered, repaired or replaced to the full warranty standard or the full purchase price will be refunded at Woodworkers discretion on return of the item.

Grade 2 Labour warranty (Three months from time of purchase)

Covers for the basic manufacturing of the item if the goods are purchased as a ‘second’ but are suitable for most uses with a little care and effort. It does not cover defects such as , but not limited to, scratches, loose or tight knots, water or other marks, timber splits, cracks, bows, twists, warps, timber colours, timber species types, glass blemishes or generally all other defects that may be difficult to hide. If the item is deemed by Woodworkers to have an assembly rather than raw material fault, Woodworkers at their discretion, undertakes to repair or replace the item to the basic warranty standard or refund the monies on the return of the item.

Grade 3 No Warranty

The item is purchased “as is” and is not covered by warranty.

The applicable warranty level is nominated on the sales docket attached to the item and disclosed on the website listing.

Yes. Our willingness to lower prices will depend on the relative demand for the items in question; how long each item has been in the orphanage, what payment method you propose (credit card fee applies) and the extent of discount already applied to the listed price. If you are purchasing a lot of joinery ($5,000 plus) a bulk discount or hardware discount might apply.

Woodworkers manufacture timber joinery, some of which uses glass.

All glass fitted and fixed to joinery manufactured by Woodworkers meets the glass standard AS 1288.

This glass standard has different requirements depending on its use and location within the building.

All areas classified as wet areas (eg bathrooms) should have safety glass.

For specific information you should check with your Certifier for building code compliance.

It is up to customers to ensure the item they purchase will conform to the AS1288 standard after installation.

Overproduction

Our computerized production system is the best in the industry but sometimes items get made twice. With literally thousands of components on the floor at any one time, it’s inevitable. Sometimes we deliberately make a second or third article of complicated joinery just in case the first article gets damaged in the latter machining processes.

Recycling

Items such as toughened glass cannot be cut or altered after manufacture but occasionally arrive the wrong size from the glass suppliers. Rather than throw it away we construct joinery (doors plus windows and more) to suit and discount it for the orphanage. We also deliberately buy manufacturing errors from our suppliers at heavily discounted prices and frame them up for the orphanage at unbeatable prices.

Consignments

Builders occasionally go broke leaving us with uncollected orders and sometimes clients order incorrectly resulting in the wrong joinery being manufactured. The orphanage provides a solution to everyone’s problem and the joinery (doors plus windows and more) finds a new home.

Samples & Ex Display Items

Sometimes prototypes are required for larger projects, or new designs are trialed for our growing stock range. When no longer required they go to the orphanage.

Scratches & Dents

Thousands of doors are moved around our workshops every day and occasionally forklift and truck damage occurs. Most items get repaired but may become undersized in the process and are discounted in the orphanage.

Seconds

Some items, for one reason or another, simply don’t pass quality control. They may have slight bows, conspicuous timber flaws or other defects that wouldn’t matter for painted situations or secondary uses. Any important defects are noted on the sale tag.

Stuff Ups

More errors occur with tape measures than any other piece of equipment in the workshop! First quality joinery (doors plus windows and more) made to the wrong size goes straight to the orphanage along with doors rebated incorrectly, glazed wrongly etc.

Timber FAQs

Woodworkers generally manufactures in Surian Red Cedar, although a range of stock doors in Pacific Maple is also available for those wishing to paint their doors. Door and window frames normally have hardwood sills. The hardwood used is usually Kwila/Merbau. Other timber species from time to time may be used. If the customer requires more information they should contact sales@woodworkers.com.au

Timber:

Surian Red Cedar:

Colour: Reddish brown.

Durability: Category 2 : Used for internal & external applications.

This hardwood timber is South East Asia’s equivalent of Australian red cedar but much more readily available.

It is sourced from sustainable yield sources in PNG, Malaysia & Indonesia and is very suited to joinery use in the Northern Australian climate.

It has a rich colour and strong grain and if properly finished with a transparent finish will look superb and stand the test of time, as can be seen by the large amount of Australian Red Cedar joinery still in use today all over Queensland and Northern NSW.

Surian Red Cedar should not be confused with the softer Western Red Cedar from North America which has a very different colour and is not well suited to the tropics.

Pacific Maple:

Colour: Pale straw or grey.

Durability: Category 2 : Used for internal & external applications.

General joinery, domestic finishing timber such as skirting, architraves, wall panelling.

Pacific Maple is the common trading name for a number of S.E.Asian hardwoods marketed in Australia. Sometimes just called Maple, the individual species names can be Lauan, Seraya or Meranti. The timber is not generally suitable for clear finishing as the colour is bland, but can be stained or painted to achieve a pleasing result.

New Guinea Rosewood:

Colour: Can vary considerably from light to dark tan or brown and pink to almost red.

Durability: Category 1 : Used for internal & external applications.

This hardwood has characteristics similar to Teak and is an excellent joinery timber due to its durability and stability. Its colour ranges can give it great character, if it is being transparent finished. It will however usually require light staining to bring the colours together.

Western Red Cedar:

Colour: Golden light to very dark brown.

Durability: Category 2 : Used for internal & external applications.

A softwood with prominent grain features but large colour variations which is very easily damaged. This North American native timber is not used for external joinery work by Woodworkers as it is predisposed to rotting.

Kwila/Merbau(Sills Only):

Colour: Golden brown to dark brown.

Durability: Category 1 : Used most particularly in exposed external use.

This hardwood timber is strong and oily and repels water naturally, making it ideal for heavy exposed elements such as the sills under joinery. Care needs to be taken with Kwila to fully seal the timber before it is exposed to any weather as it can leach badly and stain surrounding work with its tannin run off.

YES – All timber joinery has to be finished in some manner to seal and protect it.

By ‘finishing’ we mean the application of either an opaque or transparent finish applied to all 6 sides to protect it from the elements. Without a finish all timber will swell or crack and will discolour. No warranty applies to unfinished joinery.

To preserve your warranty as well as your joinery, a full coat of sealer must be applied to dry timber joinery within 48 hours of delivery. Generally timber joinery will require at least 4 coats of finish, two coats of primer/sealer or undercoat and two top coats to give luster and long-lasting protection. All joinery should be checked regularly, but the life of the finish will depend on its exposure. Joinery fully exposed to weather and sunlight or joinery in coastal areas will need more frequent maintenance. Look for signs of dryness, peeling, surface checking or discolouration.

ROSEWOOD: Woodworkers fabricates joinery in New Guinea Rosewood but does not carry a stock range in this timber. Rosewood is one of the world’s most stable & durable timbers, but has the disadvantage of large colour variations within each component. For this reason it needs to be lightly stained rather than clear finished.

KWILA/MERBAU: Woodworkers uses Class 1 hardwoods for its sills on assembled frames, usually in Kwila or Merbau. These sills can leach a dark stain onto their surrounds unless they are fully sealed on all sides to contain their natural tannins. It is essential that the underside and all faces of sills are fully sealed with compatible product to that used on the joinery before installation.

Woodworkers recommend certain products in the Sikkens range of finishes as being ideal for joinery. Please avoid water based acrylic finishes as they void your warranty. Sikkens is an oil based resin that has the advantages of

Long life in exposed conditions & easily maintained.

Easy to apply and easily re-applied over time.

Easily removable from glass.

Can be used internally & externally.

Nourishes the timber & prolongs its life.

There are 2 products in the coating system – SIKKENS CETOL HLS (sealer) and SIKKENS FILTER 7 (top coat) available in a range of tints as well as the honey clear 077 transparent finish.

Apply the first coat of Sikkens HLS within 48 hours over clean raw timber. After applying the initial coat, when dry, lightly sand along the grain of the timber using a fine (preferably sponge backed) abrasive pad or sandpaper. Do not fill nail holes etc until after the first coat is applied as unsightly smear marks will be trapped under the finish and will not be able to be removed easily. Stop holes after the first coat of sealer with an oil based wood fill putty that is darker than the timber (Walnut generally has the colour of a timber knot, whereas commercially available Cedar putties are generally lighter than the timber and do not blend in successfully).

Repeat the sealing and sanding process until a smooth even finish is achieved.

It is important that all smoothing and preparation be done at the priming/sealing stage as you should not need to sand the top coats. SIKKENS FILTER 7 (with UV filters for added protection) is recommended for the top coats as it builds quickly to a rich satin finish.

We recommend only an oil based enamel finish for joinery NOT acrylic coatings (water based). There is a great deal of difference in oil based coatings available and not all products will give you the finish that you want. Most oil finishes are formulated for weatherboards and external timber and contain very high oil levels which dry slowly and are very difficult to sand. Because joinery requires numerous coats with sanding in between the initial coats, the primer/sealer needs to be a fast drying oil paint able to sand to a fine powder. Top coats of enamel should only be applied when the base coats have been sanded smooth as you should not sand top coats for a professional finish. Avoid all dark colours for external joinery as it will attract and retain heat and can cause the joinery to warp or shrink.

Some painters prefer quick application coatings that give them a very profitable turn around but can be disastrous for the joinery and its owner. Generally speaking, if the joinery is completely internal you can use any finish, but for external items the following is a list of products you should avoid –

Polyurethane coatings, estapols and lacquers – All such finishes are too inflexible and restrain natural timber movement. They therefore crack quickly and because they retain and concentrate heat, can cause severe warping or splitting in the joinery. They also break down quickly in ultraviolet light. These finishes void your joinery warranty if used externally.

Acrylic coatings – Have the effect of wrapping your joinery ‘in plastic’ so that it cannot breathe. Coatings tend to ‘stick’ and restrict movement where, for example, sashes have to slide across each other in windows and doors. They are generally complicated to re-apply over time requiring etching and other surface keying to permit subsequent coats to bond. These finishes void your joinery warranty if used externally.

Varnishes and Natural oil finishes – Marine varnishes do not have a long life & most modern varieties have similar disadvantages to lacquers. Natural oil finishes are good for the timber but tend to be absorbed over a fairly short time so that regular recoating is required.

Water repellant preservatives – Contain repellant waxes, resins and usually fungicide to provide a temporary water barrier which breaks down progressively due to atmospheric oxidization. Can cause compatibility and bonding problems with subsequent finishes and voids the joinery warranty.

Glass Information

Woodworkers manufacture timber joinery, some of which uses glass.

All glass fitted and fixed to joinery manufactured by Woodworkers meets the glass standard AS 1288.

This glass standard has different requirements depending on its use and location within the building.

All areas classified as wet areas (eg bathrooms) should have safety glass.

For specific information you should check with your Certifier for building code compliance.

It is up to customers to ensure the item they purchase will conform to the AS1288 standard after installation.

Timber Information

Woodworkers generally manufactures in Surian Red Cedar, although a range of stock doors in Pacific Maple is also available for those wishing to paint their doors. Door and window frames normally have hardwood sills. The hardwood used is usually Kwila/Merbau. Other timber species from time to time may be used. If the customer requires more information they should contact sales@woodworkers.com.au

Timber:

Surian Red Cedar:

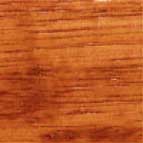

Surian Red Cedar

Colour: Reddish brown.

Durability: Category 2 : Used for internal & external applications.

This hardwood timber is South East Asia’s equivalent of Australian red cedar but much more readily available.

It is sourced from sustainable yield sources in PNG, Malaysia & Indonesia and is very suited to joinery use in the Northern Australian climate.

It has a rich colour and strong grain and if properly finished with a transparent finish will look superb and stand the test of time, as can be seen by the large amount of Australian Red Cedar joinery still in use today all over Queensland and Northern NSW.

Surian Red Cedar should not be confused with the softer Western Red Cedar from North America which has a very different colour and is not well suited to the tropics.

Pacific Maple:

Pacific Maple

Colour: Pale straw or grey.

Durability: Category 2 : Used for internal & external applications.

General joinery, domestic finishing timber such as skirting, architraves, wall panelling.

Pacific Maple is the common trading name for a number of S.E.Asian hardwoods marketed in Australia. Sometimes just called Maple, the individual species names can be Lauan, Seraya or Meranti. The timber is not generally suitable for clear finishing as the colour is bland, but can be stained or painted to achieve a pleasing result.

New Guinea Rosewood:

New Guinea Rosewood

Colour: Can vary considerably from light to dark tan or brown and pink to almost red.

Durability: Category 1 : Used for internal & external applications.

This hardwood has characteristics similar to Teak and is an excellent joinery timber due to its durability and stability. Its colour ranges can give it great character, if it is being transparent finished. It will however usually require light staining to bring the colours together.

Western Red Cedar:

Western Red Cedar

Colour: Golden light to very dark brown.

Durability: Category 2 : Used for internal & external applications.

A softwood with prominent grain features but large colour variations which is very easily damaged. This North American native timber is not used for external joinery work by Woodworkers as it is predisposed to rotting.

Kwila/Merbau(Sills Only):

Kwila

Colour: Golden brown to dark brown.

Durability: Category 1 : Used most particularly in exposed external use.

This hardwood timber is strong and oily and repels water naturally, making it ideal for heavy exposed elements such as the sills under joinery. Care needs to be taken with Kwila to fully seal the timber before it is exposed to any weather as it can leach badly and stain surrounding work with its tannin run off.